When it comes to stiffening paper, there are a number of methods available. From traditional methods like applying starch or glue sizing, to more modern methods like using spray starch or lamination. Each method has its own advantages and disadvantages and it will depend on the specific needs and budget for the project.

In this article, we will be comparing and contrasting the different methods available, discussing their cost, ease of use, and effectiveness, and providing you with a guide on how to choose the right method for your project. Whether you’re making paper crafts, bookbinding, or trying to preserve important documents, this article will give you an overview of how to make your paper stiff and durable.

4 Methods to Stiffen Paper

Applying Starch

Applying starch is a simple and effective method for stiffening paper. Starch is a natural substance that is often used in papermaking, and it can be used to stiffen paper at home with just a few tools. Here is a step-by-step guide on how to apply starch to paper:

- Gather the necessary tools: You will need a paintbrush or foam brush, a container of liquid starch, and a clean, dry surface to work on.

- Prepare the starch: If you are using liquid starch, mix it according to the package instructions. Be sure to use a clean container and utensils.

- Apply the starch: Use a paintbrush or foam brush to apply a thin, even coat of starch to one side of the paper. Be sure to cover the entire surface.

- Allow to dry: Allow the starch to dry completely on the paper. The drying time will vary depending on the humidity and the amount of starch applied.

- Repeat the process: Once the first side is dry, flip the paper over and repeat the process on the other side. Be sure to allow the second side to dry completely.

- press the paper: if desired, press the paper with a warm iron for the best results

These are the tools that you need to have, a paintbrush, a container of liquid starch, and a surface to work on.

Using Spray Starch

Using spray starch is a quick and easy method for stiffening paper. Spray starch is a concentrated liquid starch that is packaged in an aerosol can. It is easy to apply and dries quickly, making it a convenient option for stiffening paper at home. Here is a step-by-step guide on how to use spray starch to stiffen paper:

- Gather the necessary tools: You will need an aerosol can of spray starch, a clean, dry surface to work on, and a protective covering (optional) to place underneath the paper you are stiffening.

- Prepare the paper: Lay the paper on a clean, dry surface and make sure that it is smooth and wrinkle-free.

- Apply the spray starch: Hold the aerosol can of spray starch approximately 6 inches away from the paper and evenly mist the surface. Make sure to cover the entire surface, but be careful not to over-saturate the paper.

- Allow to dry: Allow the spray starch to dry completely on the paper. The drying time will vary depending on the humidity and the amount of starch applied.

- Repeat the process: Once the first side is dry, flip the paper over and repeat the process on the other side. Be sure to allow the second side to dry completely.

- Press the paper: if desired, press the paper with a warm iron for the best results.

These are the tools that you need to have, spray starch, the surface to work on, and a protective covering (optional) Please be aware that when you use spray starch, as it is an aerosol can it could produce some fumes and please use it in a well-ventilated area, and be careful as it could be flammable.

Glue Sizing

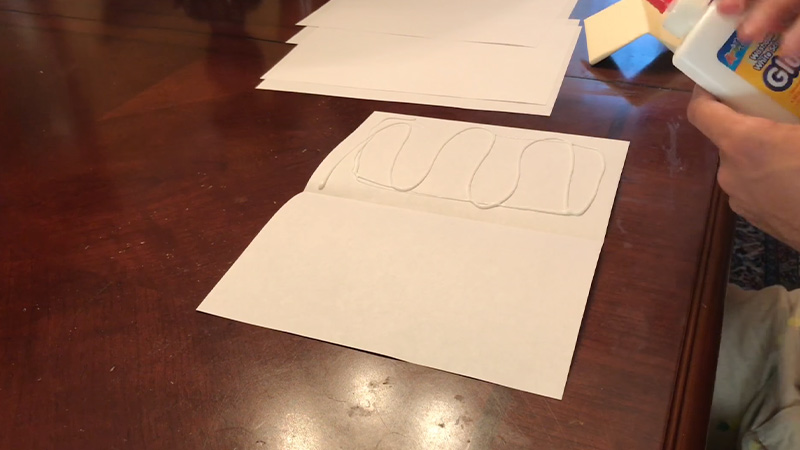

Glue sizing is a method for stiffening paper that involves applying a mixture of glue and water to the paper before it dries. This creates a stiff, durable surface that is ideal for a variety of applications such as bookbinding, paper crafts, and more. Here is a step-by-step guide on how to apply glue sizing to paper:

- Gather the necessary tools: You will need PVA glue, water, a clean container, a brush or roller, a clean, dry surface to work on, and a weight such as a book (optional).

- Prepare the glue mixture: Mix PVA glue and water in a clean container, at a ratio of about one part glue to four parts water. Mix well to ensure it is fully combined.

- Apply the glue mixture: Use a brush or roller to apply a thin, even coat of the glue mixture to one side of the paper. Be sure to cover the entire surface.

- Allow to dry: Allow the glue mixture to dry completely on the paper. It is best to put the paper under a weight (such as a book) while it dries to keep it flat.

- Repeat the process: Once the first side is dry, flip the paper over and repeat the process on the other side. Be sure to allow the second side to dry completely.

- Press the paper: if desired, press the paper with a warm iron for the best results.

These are the tools that you need to have, PVA glue, water, container, brush or roller, the surface to work on, weight (optional)

Please be aware that PVA glue is non-toxic and safe to use, but it’s best to work in a well-ventilated area and keep it away from children and pets.

Lamination

Lamination is a method for stiffening paper that involves covering the paper with a thin layer of plastic. This creates a durable, waterproof surface that is ideal for protecting important documents and photographs. Here is a step-by-step guide on how to laminate paper:

- Gather the necessary tools: You will need laminating pouches, a laminator machine, and scissors.

- Prepare the paper: Make sure that the paper you want to laminate is clean, smooth, and wrinkle-free.

- Place the paper in the laminating pouch: Take the laminating pouch, open it, and carefully place the paper inside, making sure that it is centered.

- Seal the pouch: Remove the release liner from the adhesive side of the pouch and press down firmly to seal it closed.

- Run the pouch through the laminator: Carefully run the pouch through the laminator, following the manufacturer’s instructions. Make sure the pouch stays straight while going through the laminator.

- Cut the laminated paper: Once the lamination process is complete, use scissors to trim the edges of the paper and square it up.

These are the tools that you need to have, laminating pouches, a laminator machine, and scissors

Please be aware that laminating machines could have different types, such as thermal and cold lamination, so please make sure to follow the instruction of the laminator machine you’re using.

Comparison Between Each Method

There are a number of methods for stiffening paper, including applying starch, using spray starch, glue sizing, and lamination. Each method has its own advantages and disadvantages and it will depend on the specific needs and budget for the project. In this article, I’ll be comparing each method in terms of cost, ease of use, and overall effectiveness.

Cost Comparison

- Applying starch: This method is relatively cheap as starch is inexpensive and can be found in most grocery stores.

- Using spray starch: This method is also relatively cheap. Spray starch is readily available and can be found in most craft stores.

- Glue sizing: This method is also relatively cheap. PVA glue can be found in most craft stores or online and is not expensive.

- Lamination: this method is the most costly among them, as it requires a laminator machine and laminating pouches, both of which can be expensive.

Ease of Use Comparison

- Applying starch: This method is easy to use and doesn’t require any specialized tools or equipment.

- Using spray starch: This method is also easy to use and doesn’t require any specialized tools or equipment.

- Glue sizing: This method can be more difficult to use as it requires a brush or roller to apply the glue mixture, and it also needs some amount of time to dry.

- Lamination: this method requires a specialized machine and laminating pouch, and it can be a bit tricky to use at first, but once you get the hang of it, it can be simple and easy.

Effectiveness Comparison

- Applying starch: This method is effective in the stiffening paper, but the stiffness may be temporary and the paper may become limp over time.

- Using spray starch: This method is also effective in the stiffening paper, but the stiffness may be temporary and the paper may become limp over time.

- Glue sizing: This method is the most effective in stiffening paper as it creates a stiff, durable surface. It makes the paper water-resistant and long-lasting.

- Lamination: this method creates a very durable, long-lasting, and waterproof surface, also it can protect your paper from fading, tearing, and any kind of damage.

Comparison Table Between the Methods

| Method | Cost | Ease of use | Effectiveness |

|---|---|---|---|

| Applying starch | Cheap | Easy | Temporary stiffness |

| Using spray starch | Cheap | Easy | Temporary stiffness |

| Glue sizing | Cheap | Moderate | Long-lasting stiffness |

| Lamination | Expensive | Moderate | Long-lasting stiffness and waterproofing |

It’s to be noted that this table is a generalization, the actual cost, ease of use and effectiveness may vary depending on the specific products and equipment used and the skill level of the user.

FAQs

Yes, you can use cornstarch to stiffen paper. The process is similar to using liquid starch, you would need to mix it with water to create a paste and apply it to the paper. However, it may not be as readily available as other types of starch and the stiffness may not be as long-lasting.

The drying time for starch will vary depending on the humidity and the amount of starch applied. A general rule of thumb is to allow the starch to dry completely before flipping the paper over and repeating the process on the other side. Typically, it can take anywhere from a few hours to a day for the starch to dry fully.

PVA (polyvinyl acetate) glue is most commonly used for glue sizing because it is waterproof, acid-free, and is commonly used in bookbinding, however, you can use other types of glue such as flour and water paste or methylcellulose, but they may not give the same result as PVA glue.

Yes, you can laminate just one side of a paper if you prefer, but it is more common to laminate both sides for added protection and durability.

It depends on the type of laminator machine you have. Some laminators are only capable of laminating a specific thickness and type of paper, and some are more versatile and can laminate a wider variety of papers. It’s best to check the manufacturer’s instructions for your laminator machine to see what types of paper it can accommodate.

Conclusion

Each method has its own advantages and disadvantages. Applying starch, using spray starch and glue sizing is relatively cheap and easy to use, but the stiffness may be temporary. Lamination is the most costly and requires specialized equipment, but it creates a very durable, long-lasting, and waterproof surface. Ultimately, the choice of method will depend on the specific needs and budget for the project.

Leave a Reply