When operating a sewing machine, understanding the proper direction to turn the knobs is essential for precision and efficiency. One common query that arises is whether to turn a sewing machine knob counter-clockwise.

This question speaks to the intricacies of machine sewing, where even the slightest adjustments can significantly impact the stitching process.

In this context, the directionality of turning the knob plays a crucial role in various settings, such as tension adjustments or stitch length modifications.

This guide will explore the specifics of turning a sewing machine knob counter-clockwise, shedding light on its importance in achieving optimal sewing results.

Do You Turn a Sewing Machine Knob Counter Clockwise?

No, generally, you should not turn the sewing machine knob counterclockwise. Rather, it should be turned counterclockwise.

The majority of sewing machines are designed to be operated by turning the knob in a clockwise direction.

This is a fundamental aspect of sewing machine mechanics, and deviation from this norm may lead to complications.

Let’s break down which way you turn the handwheel on a sewing machine:

Stitch Length

The stitch length on a sewing machine refers to the distance between consecutive stitches. When aiming for longer stitches, which are often desirable for tasks like basting or quilting, you would turn the stitch length knob clockwise.

This action effectively increases the distance the fabric travels between each stitch, resulting in a longer overall stitch length.

On the other hand, when precision is crucial and shorter stitches are required, such as for delicate fabrics or intricate sewing projects, turning the knob counterclockwise decreases the stitch length, producing shorter and more closely spaced stitches.

Stitch Width

Stitch width is another crucial aspect of sewing, especially when working with decorative or zigzag stitches.

Turning the stitch width knob clockwise typically widens the stitch, allowing for broader and more visible patterns.

This can be particularly useful when embellishing fabrics or creating distinctive stitch designs. Conversely, a counterclockwise turn of the knob narrows the stitch width, which is ideal for more delicate work or when precision is essential.

Adjusting the stitch width offers flexibility in achieving various decorative effects and is particularly handy for personalizing your sewing projects.

Tension Adjustment

Proper tension is vital for achieving well-balanced and even stitches. Tension adjustment mechanisms can vary among sewing machines, so it’s crucial to consult your machine’s manual for specific instructions.

However, as a general guideline, increasing tension often involves a clockwise turn of the tension knob.

This is beneficial when working with fabrics that tend to pucker or when using specialty threads.

Conversely, decreasing tension, typically achieved by turning the tension knob counterclockwise, is useful when sewing with lightweight fabrics or threads that may otherwise cause unsightly loops or loose stitches.

How to Turn the Handwheel Counter Clockwise

Turning the handwheel counter-clockwise is a simple yet crucial operation in various mechanical systems, especially those equipped with manual controls or adjustments.

Whether you’re operating a machine, adjusting settings on a device, or engaging in a hands-on activity, understanding the proper technique for turning the handwheel counter-clockwise is essential.

Here’s a general guide to help you navigate this process effectively:

Steps to Turn the Handwheel Counter-Clockwise:

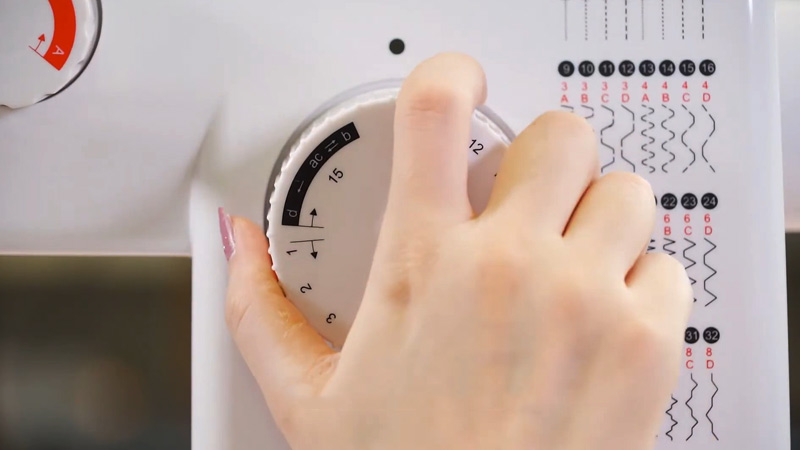

Identify the Handwheel

The handwheel is a fundamental component found in various mechanical systems and machinery. It is commonly a circular object with a protruding rim or handle designed for manual manipulation.

The handwheel aims to allow operators to make precise adjustments and control mechanisms or initiate specific functions through manual rotation.

Its distinctive circular shape often makes it easily identifiable on equipment and serves as a tactile interface for hands-on control.

Understand the Purpose

Understanding the purpose of turning the handwheel counter-clockwise is crucial for effective operation. The reasons for this action can vary based on the specific machinery or device.

Common purposes include loosening a component, reducing tension in a system, adjusting settings such as pressure or resistance, or performing any other function outlined in the equipment’s manual.

This step ensures that operators have a clear objective and avoid unnecessary manipulation that could lead to damage or malfunction.

Check for Resistance

Before exerting force on the handwheel, it’s essential to assess if there’s any resistance. Resistance could be an indication of a locked or jammed mechanism.

Forcing the handwheel under such conditions may damage equipment or compromise safety.

Investigating the source of resistance allows operators to address any underlying issues before proceeding, ensuring smooth and safe operation.

Grip the Handwheel

The method of gripping the handwheel depends on its design. Some handwheels come equipped with handles or knobs, facilitating a more ergonomic grip.

Others may have a rim without specific handles, requiring operators to grasp it directly. Regardless of the design, a firm grip is necessary for precise control.

Proper hand placement and grip strength contribute to the effective and safe rotation of the handwheel.

Position Yourself Properly

Proper body positioning is crucial when interacting with a handwheel. Whether standing or sitting, operators should ensure a comfortable and stable position to maintain control during the rotation process.

A clear view of the handwheel and sufficient space around the equipment is essential to prevent accidental collisions or interference. Adequate positioning contributes to a safer and more efficient operation of the handwheel.

Turn Counter-Clockwise

Rotating the handwheel counter-clockwise involves a specific motion that is crucial for achieving the desired outcome.

To execute this, visualize the handwheel as a clock face and turn it in the opposite direction of the clock’s hands.

If you’re facing the handwheel directly, this motion typically entails moving your hand or hands from the top toward the left.

This counter-clockwise rotation is essential for tasks such as loosening components, decreasing tension, or adjusting settings in the specified direction outlined by the equipment’s manual.

Apply Steady Pressure

As you engage in the counter-clockwise rotation, applying steady and controlled pressure is vital.

Avoid sudden or jerky movements, which could lead to unintended consequences such as equipment damage or personal injury.

A gradual and controlled application of force ensures that the handwheel responds predictably to your actions, allowing for precise adjustments without compromising safety.

Monitor the Effect

While turning the handwheel counter-clockwise, pay close attention to the impact on the system. Depending on the equipment, you may observe tension, position, or other relevant parameter changes.

Monitoring these effects is crucial for ensuring that the adjustment aligns with the intended outcome.

This step allows operators to make real-time assessments and corrections if needed, contributing to the overall efficiency and reliability of the equipment.

Follow Equipment Guidelines

Always consult the equipment’s manual or guidelines for specific instructions for turning the handwheel. Operators must be aware of Different systems with unique features or considerations.

Following manufacturer recommendations ensures that the handwheel is manipulated within its designed parameters, preventing potential issues and maintaining the integrity of the equipment.

Stop if Necessary

If you encounter any unexpected resistance, hear unusual sounds, or if the equipment manual advises against further rotation, stop immediately.

Cease the operation, assess the situation, and, if necessary, seek assistance from a qualified technician.

Ignoring signs of trouble during handwheel rotation can damage equipment, cause operational malfunctions, or compromise safety.

Prioritize a cautious and responsible approach, adhering to both general safety practices and specific guidelines provided by the equipment manufacturer.

Why Is Direction of Turning the Sewing Machine Knob Important?

The direction of turning the sewing machine knob is of paramount importance due to its direct impact on the stitching process and overall sewing experience.

Several critical aspects highlight the significance of this directional control:

Needle Movement and Stitch Placement

The direction in which the sewing machine knob is turned directly influences the movement of the needle.

This precision is crucial for accurate stitch placement, especially in intricate or detailed sections of a sewing project.

The ability to control the needle’s up-and-down motion with the knob ensures precise stitching and contributes to the overall quality of the finished product.

Thread Management and Bobbin Engagement

Turning the sewing machine knob in the correct direction is essential for effective thread management. This action often involves bringing up the bobbin thread before starting a new stitching line.

Proper thread engagement prevents initial tangles and ensures a smooth start to the sewing process.

Tension Adjustment for Varied Fabrics

Different fabrics require varying levels of thread tension for optimal stitching. The sewing machine knob allows for manual adjustment of tension settings.

Turning the knob in the right direction ensures that the tension is appropriately calibrated for the specific fabric being used, preventing issues such as loose or tight stitches.

Seam Starting and Ending Positions

The direction of turning the sewing machine knob is instrumental in positioning the needle accurately when starting or ending a seam.

This precision is vital for achieving clean and professionally finished seams. Proper control over the knob ensures that the needle is in the correct position before the sewing process begins or concludes.

Effective Troubleshooting

In instances of thread jams, fabric snags, or other sewing machine issues, the direction in which the knob is turned becomes crucial for effective troubleshooting.

Turning the knob manually allows the sewer to assess and resolve problems without causing further damage to the machine. It provides a hands-on approach to identifying and rectifying issues promptly.

Prevention of Machine Strain

Incorrectly turning the sewing machine knob can lead to unnecessary strain on the machine’s mechanisms.

Turning it in the proper direction ensures smooth operation and prevents undue stress on internal components, ultimately contributing to the longevity and efficiency of the sewing machine.

Enhanced Sewing Control and Mastery

Mastering the correct direction for turning the sewing machine knob contributes to a sense of control and mastery over the sewing process.

It empowers the sewer to handle a variety of fabrics and sewing tasks confidently, resulting in a more enjoyable and efficient sewing experience.

Hand Wheel Sewing Machine Uses

The handwheel in a sewing machine is a manual control mechanism that plays a pivotal role in stitching.

It is typically located on the right side of the machine and is used for several essential functions:

Manual Stitching

The handwheel is a manual control mechanism that allows sewers to achieve precision in stitching. By gently turning the handwheel, the needle moves up and down manually.

This manual control is especially valuable in intricate or delicate areas of a project where a high degree of accuracy is required.

Sewers can easily navigate tight corners or execute specific stitch placements, making the handwheel an essential tool for achieving meticulous craftsmanship.

Thread Management

Manually turning the handwheel is a common practice before initiating a new stitching line or after changing the thread.

This action raises the bobbin thread, ensuring a smooth transition and preventing any initial tangles.

Effective thread management is critical for seamless stitching, and the handwheel’s role in this process contributes to the overall efficiency and quality of the sewing work.

Positioning the Needle

The handwheel plays a crucial role in accurately positioning the needle. This precision is vital when starting or finishing a seam, adjusting fabric, or ensuring the needle is correctly aligned before commencing sewing.

The ability to manually control the needle position enhances the sewer’s control over the sewing process, resulting in neatly finished and well-aligned stitches.

Tension Adjustments

Certain sewing machines allow for manual adjustments of thread tension, a feature particularly useful when working with different fabrics.

The handwheel facilitates minute changes to the tension settings, ensuring optimal thread tightness for specific projects.

This manual control over tension is essential for achieving balanced and professional-looking stitches on various fabrics.

Handling Thick Fabrics or Layers

Turning the handwheel is invaluable when dealing with thick fabrics or multiple layers.

This manual control provides better handling and prevents the sewing machine from struggling, ultimately avoiding potential issues such as needle breakage or uneven stitching.

It empowers the sewer to navigate smoothly through challenging sewing conditions with confidence.

Thread Take-Up Lever

The handwheel’s role extends to controlling the thread take-up lever. This lever is pivotal in maintaining the correct synchronization of upper and lower threads, ensuring a consistent and even stitch formation.

By manually turning the handwheel, sewers can actively engage with the thread take-up mechanism, contributing to the overall quality of the stitching.

Troubleshooting

In instances of thread jams or other issues, manually turning the handwheel provides practical troubleshooting.

By slowly rotating the handwheel, sewers can identify and resolve problems without causing damage to the machine.

This hands-on approach to troubleshooting ensures a quick and efficient resolution of issues, allowing the sewing process to continue smoothly.

FAQs

Does the Bobbin Go Clockwise or Counterclockwise?

In most sewing machines, the bobbin is wound clockwise.

Which Way Do You Turn the Hand Wheel?

Generally, turning the handwheel towards you (counterclockwise) is a common practice.

To Recap

The direction in which you turn a sewing machine knob, whether clockwise or counter-clockwise, holds significance in the realm of precise stitching and fabric manipulation.

This discussion has highlighted the importance of understanding the specific adjustments associated with turning the knob counterclockwise.

Whether it’s fine-tuning tension, altering stitch length, or navigating other sewing machine settings, a nuanced approach to knob manipulation contributes to the quality of the sewing process.

By adhering to the recommended practices and guidelines, sewers can ensure smooth operations, achieve desired results, and elevate their crafting experience.

Ultimately, the directionality of turning a sewing machine knob adds a layer of skill and mastery to the art of sewing.

Leave a Reply