Dealing with the frustration of sewing machine thread shredding is a common hurdle for many enthusiasts.

It’s a vexing problem that can disrupt the flow of a project, leaving you with uneven and incomplete stitches.

Understanding the underlying reasons behind this issue is crucial for effective troubleshooting.

From the quality of the thread to the intricacies of tension settings, several factors can contribute to this vexing problem.

In this guide, we’ll explore the myriad causes behind why your sewing machine thread keeps shredding, providing practical insights and solutions to help you achieve smooth and flawless stitching in your future sewing endeavors.

Why Does My Sewing Machine Thread Keep Shredding?

There are several potential reasons why your sewing machine thread keeps shredding. Understanding these common issues can help you troubleshoot and resolve the problem.

Here are some possible causes:

Thread Quality

Using low-quality or old thread is one of the primary reasons for thread shredding. Threads can deteriorate over time, and if they’re not of good quality to begin with, they are more likely to break while sewing.

Thread Size and Type

Ensure that you are using the correct thread size and type for your fabric and project. Using thread that is too fine or too thick for the fabric can cause shredding.

Needle Choice

Using the wrong type or size of needle for your fabric can lead to thread shredding. A dull or damaged needle can also contribute to this problem.

Tension Settings

Incorrect tension settings on your sewing machine can cause thread shredding. Too much tension can strain the thread, while too little tension can result in loose stitches that easily unravel.

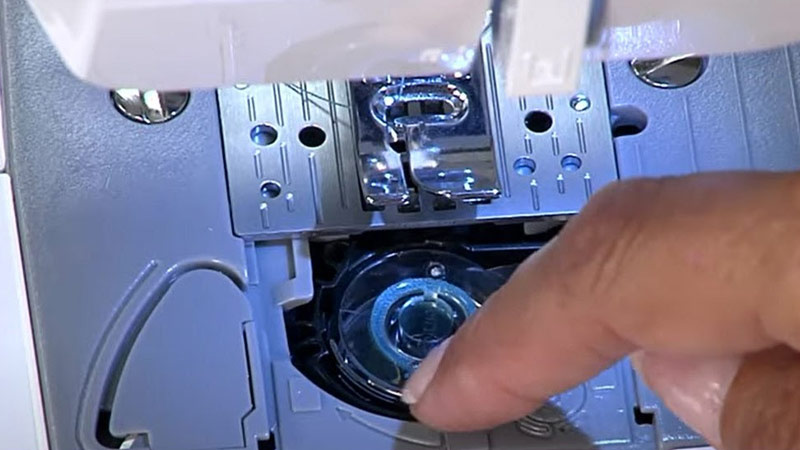

Bobbin Issues

Problems with the bobbin can also cause thread shredding. Make sure the bobbin is wound correctly and that it’s properly inserted into the bobbin case.

Machine Maintenance

Sewing machines require regular maintenance, including cleaning and oiling. A dirty or poorly maintained machine can lead to thread shredding as the thread encounters more resistance when passing through the machine.

Fabric Choice

Certain fabrics, like knits or fabrics with a lot of stretch, can be more challenging to sew with.

They may require specific needles, threads, or adjustments to your machine settings to prevent thread shredding.

Sewing Speed

Sewing too quickly can put extra stress on the thread, causing it to shred. Slow down your sewing speed, especially when working with delicate or difficult fabrics.

Thread Path Issues

Ensure that the thread is correctly threaded through the machine, including the tension discs and guides. Incorrect threading can create unnecessary friction and tension on the thread.

Stitch Length

An excessively short stitch length can cause thread shredding, especially on thicker fabrics. Adjust the stitch length to a suitable setting for your project.

User Error

Sometimes, the issue may be due to user error, such as pulling the fabric too forcefully or not guiding it properly, which can result in excessive tension on the thread.

Thread Tension Discrepancy

In some cases, there may be a mismatch between the top thread and bobbin thread tension. Adjusting the tension on either side may help resolve shredding issues.

How Can You Fix Thread Shredding in Your Sewing Machine?

If you’re experiencing thread shredding on your sewing machine, there are several steps you can take to troubleshoot and fix the issue.

Here’s a detailed guide on how to address thread shredding:

Check Thread Quality

Start by ensuring you’re using high-quality thread that’s suitable for your fabric and project. Replace any old or low-quality thread.

Verify Thread Size and Type

Make sure you’re using the correct thread size and type for your fabric. Thicker fabrics may require heavier thread, while delicate fabrics need finer thread.

Inspect Needle

Check the needle for any signs of damage or wear. If it’s dull or bent, replace it with a new, appropriate needle for your fabric.

Adjust Tension Settings

Test your machine’s tension settings on a scrap piece of fabric. Gradually adjust until the stitches are even and the thread flows smoothly.

Clean Bobbin Area

Remove the bobbin case and clean out any lint or debris. Ensure the bobbin is wound evenly and inserted correctly.

Clean and Oil Your Machine

Follow your machine’s manual for cleaning and oiling instructions. Pay close attention to the feed dogs, bobbin area, and tension discs.

Control Sewing Speed

Slow down your sewing speed, especially when working with delicate or intricate fabrics. Avoid sudden starts and stops.

Check Thread Path

Review your machine’s manual to ensure the thread is correctly threaded through all the necessary guides, tensions, and the needle’s eye.

Adjust Stitch Length

Experiment with different stitch lengths on a scrap piece of your fabric to find the optimal setting. Adjust as needed for your specific project.

Guide Fabric Carefully

Gently guide the fabric as it feeds through the machine. Avoid pulling or forcing the fabric, as this can cause undue tension on the thread.

Consider Using a Thread Lubricant

Apply a thread lubricant, such as silicone-based spray, to reduce friction and prevent thread shredding, especially when working with specialty threads or sensitive fabrics.

Prevention Is Better Than Cure

Preventing thread shredding on your sewing machine involves a combination of proper machine maintenance, selecting the right materials, and adjusting settings appropriately.

Here are some steps you can take to minimize or eliminate thread shredding:

Use High-Quality Thread

Look for thread brands that are known for their durability and strength. Quality thread is less likely to fray or break during sewing.

Consider the composition of the thread. For example, cotton-wrapped polyester threads are a good choice for many general sewing projects.

Avoid using old or brittle thread, as it can lead to more frequent shredding.

Select the Right Thread Size and Type

Consult the manufacturer’s recommendations on the thread spool for guidance on thread weight and fiber content.

Use finer threads for lightweight fabrics and thicker threads for heavier materials. Specialty threads, such as metallic or silk, may require specific adjustments to your machine and techniques.

Choose the Correct Needle

Match the needle type to your fabric. For example, use ballpoint needles for knits and sharp needles for woven fabrics.

Ensure that the needle size is appropriate. A needle that’s too small can cause excessive friction and lead to shredding.

Check Tension Settings

Test the tension on a scrap piece of fabric before starting your project. Make adjustments until the stitches are even and the thread flows smoothly.

Remember to re-check tension when switching to a different type of fabric or thread.

Maintain Bobbin and Bobbin Case

Clean the bobbin area regularly using a small brush or a can of compressed air to remove lint and debris.

Ensure the bobbin is wound evenly and smoothly. Uneven winding can cause uneven thread tension.

Keep Your Machine Clean

Follow your machine’s manual for cleaning instructions. Pay special attention to the feed dogs, bobbin case, and tension discs.

Apply a few drops of sewing machine oil to the recommended points to keep moving parts lubricated.

Mind Your Sewing Speed

Control your sewing speed with the foot pedal or machine settings. When working with delicate or intricate fabrics, slow down to reduce strain on the thread.

FAQs

Why does my thread keep shredding even with a new needle?

Thread shredding can be caused by factors beyond the needle, such as incorrect tension settings, poor thread quality, or fabric type.

How can I tell if the thread is of good quality?

High-quality thread is smooth, evenly wound, and doesn’t have frayed or weak areas. It’s also less likely to break or shred during sewing.

Can using the wrong needle size cause thread shredding?

Yes, a needle that’s too small for the fabric can cause excessive friction, leading to thread shredding. Always use the right needle size for your chosen fabric.

Why is machine maintenance important in preventing thread shredding?

Regular cleaning and oiling of your sewing machine reduce friction and ensure smooth operation.

What should I do if I’ve tried all the troubleshooting steps and still face thread shredding?

If you’ve exhausted all efforts, consider seeking advice from a professional or contacting the manufacturer for specialized assistance.

To Wrap Up

In the realm of sewing, overcoming challenges is an integral part of honing one’s craft.

The persistence of thread shredding can be exasperating, but armed with knowledge and effective solutions, it becomes a conquerable obstacle.

By delving into the intricacies of thread quality, machine maintenance, and proper technique, you empower yourself to create seamless, professional-grade stitches.

Remember, each project is an opportunity to apply these insights, refining your skills and achieving impeccable results.

So, as you embark on your sewing journey, let the vexing issue of thread shredding be but a distant memory, replaced with the satisfaction of smoothly flowing stitches and beautifully crafted creations. Happy sewing!

Leave a Reply